Introduction/Summary:

Regenerative and sustainable soil and water management for intensive crop production in protected cultivation is a key to farm profitability and crop quality. The integrated management of physical, chemical and biological components of soil can minimize the need for off farm resources and interventions with potentially toxic chemicals or pesticides. A comprehensive plan can be developed to address fertility, water and soil health issues.

Protected cultivation in high tunnels:

- alters the air and soil temperatures which can:

- accelerate crop growth

- alter water requirements

- alter soil biology and organic matter degradation

- allows regulation of soil moisture and accurate timing and placement of irrigation water,

- may prevent the leaching effect of rain which increases nutrient retention but also requires a more intensive management of nutrient/mineral balance;

- could lead to limited crop rotation that favors development of root pathogens,

- can limit soil compaction depending on management methods,

- usually accelerates weed/competitor/ground cover growth like crop growth but can limit the introduction of non-crop seeds.

A question to ask at the start is what is the goal?

Initially the goal is to manage the crops and soil so that:

- economically viable yields or income targets are obtained; (strongly influenced by the planting and rotation plan in addition to water and fertility)

- crop diseases or feeding insects that decrease the quality of the crop are minimized;

- a certifiable organic systems plan is in place;

Long range the goal is to manage the crops and soil so that:

- the crops harvested have the best possible nutrient content for human health;

- the crops harvested have the best possible flavor that encourages consumption;

- there are no detrimental crop diseases or insect feeding;

- nutrients are effectively cycled on farm or in the local food cycle/system;

The topics in this presentation include:

- Water and irrigation management

- Pre construction site and soil preparation

- Fertility Management

- Crop Rotations

- Soil and Plant Health concerns.

The results and examples of strategies presented here are based on 10+ years experience at the MSU Student Organic Farm (SOF) and my home farm, Pear Tree Farm (PTF) as well as experience from farms and farmers across the US that I have had the good fortune to visit.

Water and Irrigation Management

It is sometimes noted that when selling vegetables, fruits and flowers, we are selling fancy packages for water since often what we sell is 80% or more water. Soil moisture also influences the microbial activity needed for nutrient availability in organic systems. With high tunnel production the success of the crop is dependent on the farmer to make good irrigation choices. Irrigation needs to be managed from the perspective applied when growing transplants in containers or larger plants in pots. Irrigation management requires a good understanding of the water quality and decisions about when and how much water to apply.

What type of water?

What do you know about the mineral content of the irrigation water at your farm? Water quality is most often used to describe whether ground or surface water is contaminated with industrial, agricultural or other chemicals that may cause a health risk. Water quality is also used to describe whether water is suitable for production of plants, particularly greenhouse or nursery container grown plants. The alkalinity is a measure of bicarbonate or carbonate in the water that determines the impact on pH; hardness impacts calcium and magnesium availability; and sodium, chloride, boron, sulfur or other elements may be present at excessive levels that either raise soluble salts or damage plants through toxicity. In general for short tem (less than 10 weeks) container grown plants when compost or soil is present in the root medium, or in field production with leaching rainfall, the impact of water quality is minimal. In four season high tunnels, water quality can have important effects. Irrigation water should be tested for macro and micronutrients at least once every few years.

An example of an irrigation water suitability test is available at http://www.algreatlakes.com/lab_agr_water.php

Interpretation guidelines are also provided at: http://www.algreatlakes.com/PDF/factsheets/ALGLFS20_Interpreting_Irrigation_Water_Analysis.PDF

It is important to note that ground water from the Eastern United States where water comes primarily from granite aquifers is significantly different from ground water in the Midwestern or North Central United States where ground water is often from limestone aquifers. Common published or shared recommendations for routine applications of lime on the East Coast are often not appropriate in the Midwest where ground water is in use. On the other hand, use of municipal water drawn from the Great Lakes or other surface water may be low in minerals and alkalinity and similar to water from granite aquifers. Water analysis is the key.

Irrigation water at the MSU-SOF is representative of many areas of Michigan and the Midwest. It has high alkalinity (300+ ppm bicarbonate equivalent) and hardness (100+ ppm calcium (Ca) and 25+ ppm magnesium (Mg)). With each irrigation a small amount of lime from the limestone aquifer is applied which raises pH. In our case there is enough Mg in the water that an excess of Mg compared to Ca can occur. To adjust the pH down from values over 7.6, elemental sulfur is added at a rate of 0.5 to 1.0 lb per 20 sq ft bed and gypsum (calcium sulfate) is added at 1 lb per 20 sq ft bed if needed to maintain Ca:Mg.

I am not aware of specific cases in Michigan or the Midwest where water quality is negatively impacting high tunnel crop production. Elements of possible negative consequence are sodium chloride and boron. Collecting rain water is an option if ground water quality is not suitable for high tunnel production.

When to irrigate?

How do you determine when to irrigate? It is safe to say that it depends on factors like the stage of plant development, the soil type, and the weather conditions. Do you consider the amount of sunlight and the temperature? Or do you irrigate at some preset interval like every other day or once per week? Do you wait until seeing some plants wilt? Do you test the soil moisture with your hand or equipment? Irrigation timing is a major responsibility of the high tunnel farmer.

Both the frequency or timing of irrigation and the quantity of water applied are influenced by the stage of crop development. Recently sown seeds or planted transplants may be watered multiple times per day with light applications of water until rooting and establishment allow less

frequent and heavier applications of water.

Under high temperature conditions, lack of soil moisture / water can impact leaf expansion, flower retention, fruit development and overall plant survival. Morning irrigation is recommended to prevent sudden changes of temperature that can occur with cold irrigation water. Wet foliage also favors development of foliar diseases such as powdery mildew or blight. Wetting foliage during conditions that favor rapid drying is not detrimental unless foliar disease is already present and is spread by splashing water.

Under low temperature and freezing winter conditions irrigation is limited to windows of sunlight and warmer temperatures. Risk of cold damage increases when the foliage is wet and ice forms on the outside of the leaf. Weather forecasts are used to identify expected clear, bright conditions that will warm the tunnels and dry plants. At the MSU-SOF, the goal is to be finished watering by noon, or 2:00 pm at the latest. During the winter water is generally directed at the soil and not the foliage

How much to irrigate?

The quantity of water applied together with the soil texture (particle size) and structure determines the depth of wetting and the amount of leaching. Porous sandy soils will allow water to move downward with limited horizontal distribution compared to loam or clay loam soils which

will slow the water infiltration and allow for greater horizontal movement. If water does not go deep enough or horizontally (with drip irrigation) the rooting zone is restricted. Leaching is the movement of soluble nutrients in the water. With each irrigation, salts (Ca++, Mg++, K+, Na+,

NH4+, H+, HPO4=, SO4=, NO3–, Cl–) are moved down into the root zone or beyond the root zone if excess water is applied. Between irrigations, evaporation of water from the soil surface can also move water out of the root zone.

How much to irrigate is often described as the amount applied per unit of ground area. It might be gallons per square foot or inches of water. An estimated irrigation requirement for high tunnel tomatoes in the summer is one inch of water per week which is equal to 0.625 gallons (80 fl ounce) of water per square foot. In areas of the Midwest that get 30” of precipitation per year, that is equivalent to 0.58” per week (0.3625 gallon) or 6 to 7 fluid ounces per square foot per day if applied evenly across the year.

A 5/8 or ¾ inch hose at 40 psi delivers about 5 to 7 gallons per minute at maximum flow. At 6 gallons per minute it would take about 6 seconds to deliver an inch of water per square foot.

Drip tape is typically rated for flow rate at the number of gallons delivered per hour or minute per unit length of tape (often 100’) so calculations can be made for how long to run the system at a particular pressure and flow rate. It is also important to consider the dripper spacing (6”, 8”, 12”, 15”) with narrow spacing often preferred for tunnels. The spacing between runs of dripper is also important. While tomato at 4’ or 6’ row spacing may be irrigated with one run every 4’, there likely is an advantage to a second run to increase the wetting.

Building soil organic matter should increase both the rate of water absorption and the moisture holding capacity of the soil. Very dry, sandy, course textured soils may be difficult to rewet or hydrophobic. Multiple light applications of water is one way to rewet the soil. In high tunnels it maybe practical to add some fine textured clay soil, perhaps by first adding it during preparation of compost that will be used to modify the soil. An organic approved wetting agent, such as one made from yucca root may also provide some benefit. The volume to apply at each irrigation changes with stage of crop development. During seed germination or establishment of transplants, more frequent, light / shallow applications are made while for established plants, less frequent, heavy / deep applications are recommended in order to increase root development.

How to water?

How do you water your high tunnel? The options are fairly limited and include hose and breaker, drip irrigation, overhead sprinklers, or possibly subirrigation. Factors to consider are investment needed, employee time available for watering, ability to keep foliage dry, ability to adjust for diverse crops.

If tomatoes need 1” of water per week, for a 30’x96’ greenhouse or 2880 sq ft, 1” water equals 2880/12 = 240 cu ft of water or 1800 gallons (7.5 gal/cu ft) or the 0.625 gallon calculated earlier. If a hose runs at 5 gal/minute, it would take 1800/5 = 360 minutes or 6 hrs/wk to irrigate. At $7/hr that’s $42 per week. How much does a drip system cost? The cost of the drip system is clearly justified and will save time and increase crop quality.

Multiple short hoses may increase labor efficiency over dragging long hoses through the high tunnels. A high quality hose end breaker that creates a finer shower of water without excessively restricting water flow will increase efficiency and reduce soil compaction. Put a quarter turn valve on the operating end of each hose so the flow is easily managed.

Drip irrigation is an efficient way to slowly apply water. The spacing and flow rate of drippers can be selected to optimize water placement. At the MSU-SOF, each drip line off the main header has an on-off control so beds can be managed individually. One source in the Midwest that provides an on-line catalog with examples is http://www.trickl-eez.com. If drip irrigation is used consistently without other forms of overhead irrigation, it is

possible that a layer of soluble salts may accumulate at the soil surface. These may be valuable nutrients that are not available to the root zone. An occasional overhead irrigation with a hose and breaker or with a sprinkle system is recommended to move the nutrients into the root zone.

The presence of either organic or plastic mulch can reduce evaporative water loss and the movement of soluble salts to the soil surface. Mulch is a valuable water and fertility management tool that is often not fully considered when developing a system.

Overhead irrigation with spray nozzles can also be an efficient way to uniformly apply irrigation water if water quality allows. One concern in the Midwest is that high alkalinity, hard, high iron water will leave residue on the plastic film greenhouse roof and may stain the plastic brown. I have not measured the actual reduction in light transmission but assume that it is significant. Another concern is the potential to spread foliar disease. Water on foliage is not inherently detrimental. It may actually be a type of foliar fertilizer. However, if foliar diseases are present in the high tunnel, overhead irrigation may hasten the spread of the disease. Water is typically applied so that foliage is dry before darkness.

Irrigation methods are influenced by the soil texture. Courser, higher sand soils will retain less water and are easier to leach so need to be watered more frequently with less volume. Finer, higher clay soils will retain more water without leaching. Here the concern is to not apply an excess of water that limits the aeration of the root zone (over watering). In greenhouse and nursery containers, if rapid leaching is occurring due to dry root media, the application of water may be “pulsed” by turning the system on and off for shorter periods of time to increase water absorption and efficiency.

With very porous sandy or hydrophobic soils, it may actually make sense to put a layer of water barrier polyethylene film several feet below the soil surface. This method is being researched at MSU for field production and has resulted in increased yields and water efficiency on sandy soils. We have raised beds in a heated greenhouse that are lined with polyethylene and have been in use for over 15 years with primarily compost and mineral amendment and with no leaching.

Soil Preparation Prior to Construction

What steps are important to prepare the site and soil prior to construction? One of the first concerns is to insure that rain water can move away from the high tunnel. Soil type and slope of the surrounding area will determine if drain lines are necessary. At the MSU-SOF it is essential that drain tile was installed around the hightunnels to move the water away. A 1 inch rainfall on a 30’x96’ high tunnel can displace 1725 gallons of water.

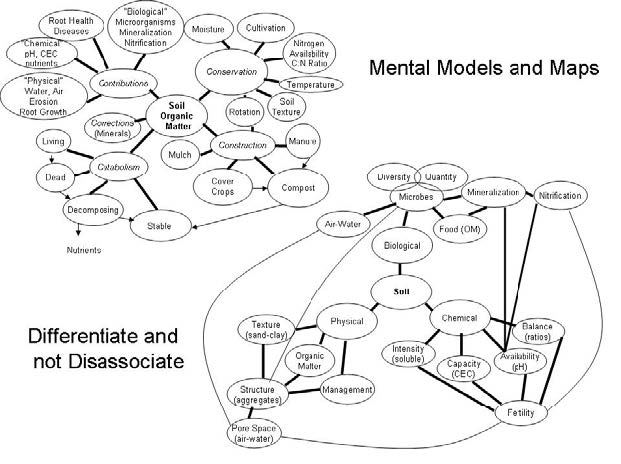

To improve the return on the investment, the soil needs to be properly prepared for intensive crop production. Prior to construction, cover crops, compost, minerals or amendments, and sheet composting can be used to build soil organic matter and increase fertility (see diagram at end of article). Insufficient pre construction soil preparation has been a limitation for many Michigan high tunnel projects.

With sandy soils and sites where water can easily percolate or move away, ground posts can be driven into the unmoved soil. On heavier soils with slow percolation topsoil from the perimeter of the structure can be moved to the center using a front end loader to create a large raised bed in the center. The raised bed can help with soil moisture and drainage of cold air in the winter. Compost can be added to the raised bed if needed and incorporated.

A common question is whether to use cover crops in the high tunnel? In general, once the structure is built, the production area if very valuable and the time between crops is short. If a diverse crop rotation can be maintained, it is not essential to use tunnel cover crops. If there is time in the schedule, buckwheat is a short term, warm season cover crop that breaks down quickly. Oats can also be tilled in after a short time of grown and will grow in cool seasons. Both of these provide some diversity to an intensive high tunnel vegetable rotation.

Fertility Management

A graphic summary of the key components of soil and soil organic matter management is provided at the end of this document. Soil fertility in an organic system is a balance of managing physical, chemical and biological components and the organic matter that feeds the system. Based on experience of high tunnel growers and my own experience, there are at least three key components to long term successful high tunnel fertility management.

- Soil Testing. Soil testing to determine the nutrient availability (pH) and balance is perhaps even more important than it is in the field. Results of our annual soil testing over nine years will be presented and interpreted.

- Compost. Compost seems to be the most important soil fertility management tool for the high tunnel. Soil testing to determine the nutrient availability (pH) and balance is perhaps even more important than it is in the field. Results of our annual soil testing over nine years will be presented and interpreted.

- Rotations. The variation in crops grown in the tunnel will influence whether cover crops are needed to maintain soil fertility and health.

Soil Testing

Sample Collection. A long time mantra related to soil testing is that the analysis can only be as good as the sample collected. Small variations in sampling method can result in fairly large variation in results. Important variables include the season or time of year, recent irrigation practices, the depth of the sample, and whether the surface layer of soil and loose organic matter is included in the sample. A common recommendation is to have one person collect all the soil samples so the process is uniform. When sampling from a high tunnel, assuming the soil and crop growth in a tunnel is uniform, samples from 6 to 10 cores are collected and well mixed in a clean bucket before collecting a subsample, usually 1 to 2 cups, of the total for analysis.

Soluble salts move with soil moisture. Under drying conditions with little or no mulch or plant cover, as much of 50% of the water loss can occur due to evaporation from the soil surface (as opposed to transpiration from a leaf surface). With soil evaporation salts present in the soil solution are left behind at the soil surface. While many high tunnel operators have noticed this accumulation of salts, there are not examples of documented problems or crop yield reductions due to the salt layer. A sample of the salts present can determine if there are primarily essential nutrient salts or contaminants such as sodium and chloride.

Much has also been written about the value of a deep root zone to increase the volume of soil available for root exploration. Common sense would expect that a greater rooting volume is particularly important when the nutrient levels are low or when nutrients are leached to greater soil depths due to rain. But what about the case of a high tunnel where nutrient levels can be increased without a threat of loss by leaching or soil erosion? Standard soil sample recommendations are for sampling to a depth of six inches. It may be beneficial to also sample at deeper depths, such as to 12 inches or from 12 to 24 inches to evaluate the nutrient levels in an extended rooting zone. A deeper nutrient rich rooting zone may be beneficial when leaching can be prevented or when producing nutrient dense food is desired.

Analytical Methods. Methods used for field sample analysis are also appropriate for high tunnels. Dried soil samples are ground and or screened to provide a uniform sample so that only a small scoop (1 to 3 teaspoons) of soil is extracted with a dilute acid that estimates both

the soluble nutrients and the available reserve of nutrients. Soil pH is tested on a separate sample. Nitrate-nitrogen is not usually analyzed but can be if requested, which is a good idea for high tunnels. The amount of K, Ca and Mg extracted are used to calculate an estimate of the total cation exchange capacity (CEC). The balance of the three elements are also calculated. Common extract methods can include the Bray, Olsen or Mehlich extracts. Each laboratory will provide interpretation guidelines for the method used.

However, additional sample methods may be useful. Greenhouse peat, bark or compost based growing media are often tested with a water extract using the Saturated Media Extract (SME) method. As much as a cup of soil or medium that has not been dried or ground is moistened with water and then the solution is extracted using a vacuum funnel. The extracted solution is analyzed and results report total soluble salts as electrical conductivity and soluble nitrogen as nitrate and ammonium nitrogen. In addition the P, K, Ca, Mg, Na and Cl in parts per million (ppm) are commonly reported. The micronutrients Fe, Mn, Zn, Cu, B and Mo may also be reported if requested. For rapid growth conditions with frequent irrigation, ie conditions often found in a high tunnel, the SME provides a picture of available nutrients at one moment in time.

Interpretation and Recommendations. Another common soil testing mantra is having samples analyzed without spending the necessary time interpreting the results is a god way to waste money and time. Results are best entered into a spread sheet program so that trends over time

can be compared. In general, results from high tunnel samples can be interpreted just as field samples but higher nutrient levels may be both acceptable and desirable. Some common guidelines for vegetables are as follows:

- Soil pH: above 6; range of 6.5 to 7.5 as a target; above 7.6 may lead to low micronutrients; lime is frequently recommended for routine additions but these may not be needed in the Midwest US with irrigation water from limestone aquifers. Choice of either high Ca lime or dolomitic lime (Ca and Mg) is important and influenced by cation balance; avoid excess Mg. For samples over pH 7.7, if crop growth is limited, sulfur can be added to lower pH. For our soil at the MSU-SOF, rates of 0.5 to 1 pound per 20 sqft are necessary which is in the range of a ton per acre, to keep the pH in the mid 7’s.

- Soil Nitrate: less than 20 ppm low but acceptable if crop growth is good, between 20 to 40ppm moderate, 40 to 60 high and greater than 60 a possible concern.

- Soil P: above 20 ppm desired; range of 25 to 50 as a target; 100 to 250 as high but no detrimental effects anticipated if soil is not leaching or erosion is not a concern.

- Soil K: above 150 ppm; range of 150 to 300 as target; cation balance of 3 to 8%

- Soil Ca: above 1000 ppm; range 1000 to 2500; cation balance of 65 to 75%

- Soil Mg: above 60 ppm; range of 60 to 120 as a target; higher levels may negatively impact Ca and K availability. (We have 400 to 500 ppm in tunnels at MSU.) cation balance of 10 to 20%

- Soil test values reported in ppm from a 6”deep soil sample are multiplied by 2 to provide an estimate of the number of pounds per acre of available nutrient.

An interpretation for A&L labs: http://www.allabs.com/publications/soiltestreading.pdf

A useful set of recommendations from North Country Organics designed for tests from A&L labs: http://www.norganics.com/applications/soiltestinterp.pdf

Additional Organic Fertility Amendments

Based on soil test results, a variety of amendments can be added either to the compost or the directly to the soil in the high tunnel. As previously noted, at the MSU-SOF sulfur and gypsum are applied based on soil test results to manage pH and Ca:Mg issues from our irrigation water quality.

A valuable discussion of the topic of preparation of complete organic fertilizer (COF) is presented by Steve Solomon in the book “the intelligent gardener – Growing Nutrient Dense Food”. As introduced above, the soil analysis is evaluated to determine what nutrients need to be added and or balanced. After considering what nutrients can be provided or partially provided using compost, nutrient sources suitable for an organic systems plan such as those listed in the table above are selected, blended and then added at the necessary rate. Often a seed, alfalfa or blood meal to provide N is blended with rock phosphate, potassium sulfate and micronutrients as needed based on the soil test.

Compost

The quality and characteristics of the compost can vary dramatically and must be considered during selection and prior to application. A compost nutrient analysis helps identify appropriate rates. Compost analysis can be done like a plant tissue analysis were the total mineral content is determined (“total”) or can be done as a water based saturated media extract (SME) where the soluble nutrients (available) are determined. Both analyses are important to characterize a compost. The amount of available nutrients is usually dynamic and will change monthly for at least the first year the compost is maturing unless the compost is very dry (<30% moisture) or very cold (<40oF). Other factors to consider are plant based or manure based; the age or maturity; and whether the compost is stored outside and cold vs inside and warm. After the thermophilic phase of composting is completed and the pile is stable, cover compost stored outside with polyethylene film or landscape fabric to prevent leaching of nutrients or dispersal of the compost by wind.

Based on several years of experience at the MSU SOF, compost made from approximately equal parts by volume of grass hay (first cutting), legume hay (second cutting), straw, softwood shavings, aged leaves, sphagnum peat and soil in equal parts makes compost with good structure, nutrient availability and water holding capacity. The mixture described is close to a 1 part “brown” and 1 part “green” ratio that will provide a starting C:N in the range of 25:1. The amount of straw and softwood shavings can be doubled (2 brown to 1 green or closer to C:N 35:1) and still result in good quality compost that will heat during composting. The cost of materials would be about $30-45/cuyd. Up to 10% by volume manure can also be added if more phosphorus or nitrogen are desired in the finished compost. The winter bedding from our mobile chicken housing, either straw or shavings or both, are usually added to the farm residue pile in the spring. This pile also includes produce residue, crop residue and weeds not

containing seeds. Straw is added as the pile accumulates but the pile does not heat. The cold composted contents of this pile are added to the fresh materials listed above so that heating appropriate for the organic systems plan is attained. This compost is made in the summer, covered for the winter, and then used beginning in February for spring plantings.

Manure based composts are expected to have higher nitrogen and phosphorus availability and the use of manure based composts in high tunnels without leaching needs to be done with caution or restraint to avoid over fertilization. Based on our experience the use of dairy or poultry manure is not recommended except as an initial compost application to boost nutrient levels during site development.

Our experience has been that organic inspectors and certifiers will more closely scrutinize compost production records when manure is a component than when a plant based recipe as described above is used.

A key component of the long term success of the MSU-SOF high tunnels is believed to be the use of a primarily leaf mold based compost as one of the annual compost inputs. One of our suppliers has a very large stockpile of aged (10+years) municipal leaves. This screened compost product is typically added to the tunnels during August and September plantings. Aged leaves can be a good source of nitrogen if leaching has been minimized.

Rates of Compost application or use:

- MSU SOF: five gallons per 20 sq ft to 7.5 gallons (1 cuft) per 20 sq ft. for plant based compost made with the recipe mentioned above or for leaf mold. (25 gallons/100 sqft is equivalent to 54 cuyd/acre or at estimated bulk density of 900 lbs/cuyd would provide a rate equivalent to 24 ton/acre. Based on the soil conditions the rate may be increased to 7.5 gal (1 cu ft) per 20 sqft bed

- Eliot Coleman and Steve Moore recommendations for plant based composts range from 12 to 40 gallons per 100 square feet = 26 to 86 cu yd/ acre or about 10 to 40 ton/acre.

- Slack Hallow Farm (From High Tunnels Manual) – 40 ton/acre to start tunnel and then 5 gal per 40 square feet.

- For a 30’ x 96’ or 2880 sqft tunnel at 70% bed space (2016 sq ft) and 25 gallons/100 sq ft would take 2.5 cu yd of compost and at $30/yd compost the cost for all would be $75 (plus delivery (or 25 lbs of tomatoes at $3/lb which could happen on about 7 sq ft of growing space). The cost of the best compost available is clearly justified.

In a separate document, analytical results of composts made at MSU or at local farms have been summarized.

Compost test interpretation: http://ohioline.osu.edu/anr-fact/0015.html

Example analytical values or ranges:

Worm Compost, Vermicompost or Vermicasting

Another valuable nutrient resource for high tunnels that can be produced on farm or purchased is worm compost. While worm compost can have more available nutrients than thermophilic compost, the level of nutrients is strongly influenced by the feedstock inputs, just as with thermophilic composting. Starting in the summer of 2010 we have been using kitchen preparation residue (KPR) and occasionally post consumer food waste mixed with feedstocks such as leaves, straw, hay, newspaper, office paper to produce worm compost. We have over wintered the worms in an interior tunnel inside a high tunnel. Worm compost can be added during the production of vegetable transplants, during transplanting or during crop production if additional available nutrients are needed. For a 24 page document providing worm compost production and use recommendations see: www.hrt.msu.edu/faculty/biernbaum .

Crop Rotations

The organic systems plan and organic certification requires crop rotation. It is clearly not possible to grow only tomato or related crops in a high tunnel and achieve organic certification. However, tunnel based rotation schedules for 12 month production can be much different that field based rotation schedules. For example, can tomato production every other summer be justified if in the time between tomato crops there are four or five other unrelated crops?

High tunnel crop rotations at the MSU-SOF generally focus on early and late plantings of cool season and warm season crops (four categories total). Another variable is the residency time since some crops like head lettuce or root crops are harvested once (short residency) while other crops such as kale, chard, or fruiting crops are harvested over long periods of time (long residency). From a crop family grouping some major groups are: 1) lettuce and related leafy greens for baby leaf salad mix (multi harvest) or as heading crops (single harvest); 2) Brassicas for salad and cooking greens; 3) solanaceous crops (tomato, pepper, eggplant); 4) root crops (turnip, carrots, beets, radish) and 5) cucurbits (cucumber, summer squash). A separate document covering crop rotations is available.

High Tunnel Soil Related Pest and Disease Concerns:

These are three potential high tunnel problems that can be devastating to production. You want to learn how to prevent or avoid these problems prior to getting them.

- Sclerotinia: a fungal decomposer that “takes the fun out of growing greens”.

- http://organic.kysu.edu/SclerotiniaVideo.shtml ;

- http://organic.kysu.edu/biofumigation.shtml ;

- http://aunaturelfarm.homestead.com/ ;

- Symphylans: a soil insect that feeds on living roots and stunts peppers and other crops.

- See ATTRA: http://attra.org/attra-pub/PDF/symphylans.pdf ;

- High Tunnels manual; large amounts of fresh organic matter or dried leaves may increase the probability of an infestation.

- European Cutworm – can over winter in the hoophouse; destroyed the better part of a 30’x96’ fall high tunnel planting at the SOF; pyganic or Bt were not effective. Several weeks of chickens feeding in the tunnel cleaned up the larvae from the soil.

References:

- ATTRA – soil management series https://attra.ncat.org/

- Eliot Coleman – New Organic Grower, Four Season Harvest, and Winter Harvest Manual

- “High Tunnels: Using Low Cost Technology to Increase Yields, Improve Quality, and Extend the Growing Season.” – http://www.uvm.edu/sustainableagriculture/hightunnels.html

- High Tunnels web site and list serve: www.hightunnels.org

- Resources available at http://hoophouse.msu.edu

- Managing Diseases of Organic Tomatoes in Greenhouses and High Tunnels, July 2009 http://www.extension.org/article/18337