Introduction

Insect pests are one of the major problems in organic production systems. Crop damage from insect pests can occur via direct feeding or egg-laying, contamination with feces, or disease transmission; loss in yield or marketability of

vegetables in the absence of Integrated Pest Management (IPM) can be nearly 100 percent. Organic IPM practice consists of a three-tiered approach consisting of systems-based practices, mechanical tactics, and biorational insecticides. Mechanical tactics encourage the use of physical barriers for pest exclusion. Some popular pest exclusion tactics include the use of floating row covers for protection against flying insects, bagging fruits, and installing metallic collars around transplants to protect them from cutworms and armyworms. In all these cases, a barrier is created between the insect pest and the host plant for short-term protection.

This bulletin provides preliminary research data and field observations about the success of shade cloths as a more permanent barrier system around the high tunnels; this is a high tunnel pest exclusion (HTPE) system that has been developed by Alabama Cooperative Extension at Auburn University, and is an immediately useful technology for small producers in the Southeast. Such modified high tunnels may resemble ‘net houses’ which are sealed structures

designed to exclude insect pests.

Net Houses

Net houses are popular in many European, Asian, and African countries where there is a lack of effective pesticides for insect pest control or high demand for organic crops with little or no use of biorational pesticides. For example, in Africa, net houses made of 25-mesh mosquito nets were effective in reducing diamondback moths, cutworms, and loopers by 66-97 percent. Chinese researchers have shown 90 percent reduction in the incidence of tomato yellow leaf curl

virus due to significant reduction in whiteflies using a 50-mesh insect net house. In Alabama, a large 50-mesh net house was effective in nearly eliminating hornworms, tomato fruitworms, loopers, armyworms, stink bugs, and leaffooted bugs from tomatoes and bell peppers (read full article in the Journal of NACAA, http://goo.gl/uItIyS). However, use of fine insect netting for a permanent system is an expensive proposition and many farmers may be reluctant to adopt such a system due to possible side-effects (e.g., exclusion of all beneficial insects).

The authors of this bulletin have been testing various low-cost pest exclusion systems suitable for high pest pressure areas, which lead to the integration of readily available crop production technologies like high tunnels (popularized nationwide with USDA-NRCS programs) with the use of shade cloths (generally used over the high tunnels) for plant protection. As discussed herein, shade cloths installed on the sidewalls of a high tunnel can provide significant relief to

producers from insect pests. Several useful observations from producers using the HTPE system are included to corroborate trends seen in laboratory studies. Auburn University continues to work with other commercial high tunnel producers to evaluate other exclusion materials and refine the IPM recommendations. Online training videos for pest exclusion tactics, including the HTPE system, are listed at the end of this bulletin.

Key Aspects of HTPE

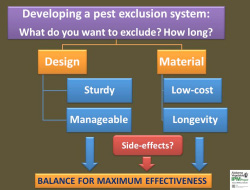

There are two basic principles of an effective pest exclusion system for permanent structures, as outlined in (Figure 1):

Figure 1: Basic elements of insect pest exclusion system that

balances design and material for maximum effectiveness.

1. Design: The critical step is to decide what pests need to be targeted for exclusion. Design using appropriate material is important to the overall success. Good design can last multiple years with high returns on investment. Incorporating pest exclusion systems with high tunnels is an easy step forward since the design has already been standardized by the industry.

2. Material: Choice of a proper material for pest exclusion is critical and there are a variety of choices available today. Ideally, pest exclusion material should be low-cost with adequate longevity. However, these two aspects may not be easily matched. For example, a low-cost material like Super Light Insect Barrier (Gardens Alive, IN) is a translucent polypropylene fabric that is an excellent material for pest exclusion, but it has not been long-lasting in university tests.

Heavy 50-mesh insect screens sold commercially by many greenhouse companies can be long-lasting, but expensive and cumbersome for large structures. Pest exclusion systems can also have some unintended effects that have to be taken into consideration. For example: 1.) Shading of plants affecting plant growth and maturity; 2.) Loss of air movement leading to disease issues; 3.) Loss of natural enemies due to non-selective exclusion. An HTPE system with 30 to 50 percent shade cloth can help deal with the above issues and maximize benefits for producers. High tunnels can be easily modified with shade cloth to serve as a barrier for keeping many large insect pests outside the crop. The goal of this system is to PREVENT insect pest establishment and reduce the overall pest pressure.

The goal is NOT to exclude ALL pests or beneficial insects. In other words, an ideal HTPE system should have a good balance of stopping pest species while allowing beneficial insects to colonize the plants.

HTPE Studies in the Laboratory

Figure 2: High tunnel models with 30 percent to 50 percent shade cloths on the sidewalls and endwalls for rapid insect behavior studies.

Laboratory studies have been conducted on some insect behaviors using 10 inch by 5 inch high tunnel models fitted with 0 (control), 30, 40 or 50 percent woven shade cloths manufactured by Grainger (Lake Forest, IL) or Green-Tek (Janesville, WI). Figure 2 compares the various HTPE models to show the differences in materials visually. The shade cloth pieces (single layer) were tightly stretched and secured around the sidewalls and endwalls of all models. The models were housed in glass display cases bought at a craft store, and insects were released under the glass for testing.

Insect pests studied with models included cabbage loopers moths, Trichoplusia ni (observational study) and leaffooted bugs, Leptoglossus phyllopus (replicated study). Beneficial insects tested included commercially available convergent lady beetles (Hippodamia convergens) and green lacewing adults (Chrysoperla rufilabris). In all cases, insects were released inside the glass cage and maintained at optimum temperature in the dark for 24-48 hours. Table 1 provides a

summary of observations. This laboratory study indicated that a 30 to 50 percent shade cloth-based HTPE system can exclude large moths with a wingspan of 1.2 inches or more. Leaffooted bug adults can be stopped using 40 or 50 percent shade cloths, but not with a 30 percent fabric due to large openings. Leaffooted bugs have the habit of exploring their habitat and the adults are very good in exploiting any weakness in the structure. Looper moths are good flyers but did not explore by walking the cloth surface, and remained outside.

Convergent lady beetle adults were very good at exploring the artificial habitat and both 30 and 40 percent shade cloth allowed their movement. A 40 percent shade cloth slowed down entry of lady beetles, but did not completely exclude them. A 50 percent shade cloth completely excluded lady beetles from the high tunnels.

Green lacewings, a popular beneficial insect of choice among organic producers, can be excluded with 40 or 50 percent shade cloth on the side-walls. Adult lacewings, with their large net-like wings, are not able to penetrate those barriers.

Table 1. Physical Exclusion of Insects Using Various Shade Clothes with High Tunnels

| Type of shade cloth and what it will exclude | ||||

| Insect | Growth Stage | 30% Shade Cloth | 40% Shade Cloth | 50% Shade Cloth |

| Cabbage Loopers^ | Adult Moths | Yes | Yes | Yes |

| Leaffooted Bugs^ | Adult Bugs | No | Yes | Yes |

| Cucumber beetles* | Adults | Unknown | Unknown | Yes |

| Squash Bugs* | Adults | Unknown | Unknown | Yes |

| Convergent Lady Beetles^ | Adults | No | No | Yes |

| Green Lacewings^ | Adults | No | Yes | Yes |

| ^ Based on laboratory-based insect behavior studies using models * Grower observations in field |

||||

Construction of HTPE in the Field

Alabama vegetable producer Will Mastin has developed a unique method to install the 50 percent shade cloth on the sidewalls and endwalls of his high tunnel. He chose 50 percent since he wanted to exclude sucking insect pests and armyworms from his high-value crops like cherry tomatoes, hydroponic lettuce, and small herbs.

Will Mastin now has four tunnels with an HTPE system (including one with SARE Producer Grant funds), and a small germination/hardening room for his transplants with the exclusion system. He uses a staple gun and a small piece of drip tape over the fabric to staple the fabric on wooden support beams and base boards. He uses metal clamps to secure the fabric at the corners and this gives a proper seal. With adequate amount of fabric, he ensures full coverage of the sidewalls and half of the endwalls to improve ventilation. The woven fabric must be extended tightly to extend the pores. He practices strict sanitation inside and outside the tunnels resulting in reduced build-up of insect pests in the long run. He also integrates other pest management tactics, like the use of sorghum-sunflower mixed trap cropping for deterring leaffooted bugs away from his tomatoes (http://www.aces.edu/anr/ipm/Vegetable/trapcropmodule) and bio-pesticides for controlling smaller pests inside the tunnels and open field crops.

Producer Steve Carpenter, who farms in a relatively low insect pest-pressure region of the Tennessee Valley, has installed a 30 percent insect netting to block moths from his cherry tomatoes. He also grew some beans in the tunnel. He uses a similar method of installation as Will Mastin with two sidewalls fitted with shade cloth. With a large pore size of a 30 percent woven shade cloth, there was no need to replace endwalls with netting where he has sliding doors. He is considering putting a curtain of shade cloth over the door that will block insects even when the door is kept partially open to cool down the structure. Carpenter also uses trap crops of sorghum and sunflower near his high tunnels along with use of biopesticides.

In this way, both producers use multiple IPM strategies for full benefit to their small farms. A third on-farm test site is under construction in Alabama to test 40 percent shade cloth in the open field.

Cost Effectiveness

Figure 4. Row covers or fine insect screens

installed over low-hoops can provide additional

crop protection from small insect pests when

installed early in the season.

Currently, on-farm studies with HTPE systems are underway at three locations in Alabama. Per our experiences, the cost of a 40 percent woven shade cloth (customcut to our specifications by Poly-Tex Inc., MN) around three sides of a standard high tunnel (2 sidewalls, 1 endwall) was under $420. The cost of a 30 percent woven shade cloth for the sidewalls of a standard high tunnel was under $250. As stated earlier, costs can be significantly higher than our figures depending on the quality/density of material and size of the high tunnel. Producers are encouraged to fully research the cost of materials and discuss designs with vendors for appropriate pricing of the material. When in doubt, contact your Extension personnel for more information and guidance.

Overall HTPE System Recommendations

- Remember, not all insect pests can be excluded when using shade cloths. Know what you want to eliminate, then design and choose materials to reduce the cost of the HTPE system. Secure shade cloth or fabric tightly around corners for full benefit.

- When choosing a shade cloth, choose one with the largest pore sizes that will eliminate your target pest. Watch for reduced air movement when using dense materials that can cause disease outbreaks.

- Use additional row covers or materials like Super Light Insect Barrier® (Figure 4) inside high tunnels in addition to netting on the sides to temporarily stop small insect pests early in the season. Super Light Insect Barrier (sold by Gardens Alive.com) works well to keep aphids and flea beetles at bay if installed immediately after transplanting tomatoes and egg plants (~85 percent light penetration and trapped heat helps too!)

- When possible, use appropriate beneficial insects with the HTPE system before a pest outbreak. Some popular vendors include Arbico Organics, Gardens Alive, and Rincon-Vitova. Lacewings released inside a 40 percent net house can be expected to remain in the structure. For lady beetle, use a 50 percent or denser material to contain the beneficial insect. Minimize the use of organic insecticides inside high tunnels to protect beneficial insects.

- Integrate other IPM tactics along with pest exclusion for full benefit and keep careful records.

- Research continues on the effectiveness of an HTPE system with various other material and insect pests. Researchers are evaluating low tunnels for community gardens and urban farms where pest exclusion offers great benefits. Contact the lead author for details.

Producer Will Mastin inside high tunnels modified with 50% shade cloth on sidewalls to exclude insect pests.

Alabama Farmer Experiences with HTPE Systems: Will Mastin, Silverhill

- Developed a hybrid tunnel to protect lettuce, tomatoes and herbs with plastic on top and 50 percent woven shade cloth on sides secured tightly under the roll-up sidwalls. Shade cloth on the endwalls improve ventilation and can reduce diseases like blight.

- Timely installation of netting is critical for exclusion to work. If insects find the doorway open, then they will rapidly enter the structure.

- High tunnels modified into net houses caused immediate noticeable reduction in pest pressures on crops. Cherry tomatoes had less than 10 percent leaffooted and stink bug damage compared to 40 percent loss in the open field crop.

- Biggest difference in insect control was seen with armyworm caterpillars. There were only 3 caterpillars in one row of netted tomatoes inside the tunnel compared to 135 caterpillars in the open field untreated crop.

- Insects can adapt to the presence of insect netting. For example, armyworms laid eggs in bunches on the netting similar to the observations of Alabama Cooperative Extension specialist Ayanava Majumdar. The eggs were washed off with a blast of water from inside the tunnel.

Producer Steve Carpenter inside his high tunnel with 30% shade cloth to exlude large moths and grasshoppers.

- Exclusion of beneficial insects is another problem – similar to the observations by researchers. Pollination was not found to be an issue. Steve Carpenter, Hamilton

- HTPE was one of the best IPM tactics Steve Carpenter has used for his high tunnels. It gave results in the short-run with very good quality of produce and minimum spraying.

- Shade cloth was very successful in keeping out large moths like hornworms, Japanese beetles, and grasshoppers from the tunnel. Strict weed control around the tunnel is critical for grasshopper control in addition to netting.

Additional Resources for Producers

Figure 5. Alternative Vegetable IPM Slide Chart, funded by SARE, is available to producers.

The Alabama Extension Vegetable IPM Project website (http://www.aces.edu/go/87) provides access to many popular articles and videos about insect pest exclusion systems. Direct links to IPM training videos is also provided at the end of this bulletin.

To stay informed about IPM research, readers are encouraged to sign up for the Alabama IPM Communicator newsletter by visiting http://www.aces.edu/ipmcommunicator.

Producers can request a copy of the Alternative Vegetable IPM Recommendation Slide Chart (Figure 5) funded by a SARE grant; e-mail your request to bugdoctor@auburn.edu. Producers in Alabama can also receive a free copy of the High Tunnel Crop Production Handbook for New and Beginning Farmers from a commercial horticulture regional Extension agent. This handbook is also available as an iBook for mobile devices.

Direct Link to Net House Training Videos (Alabama Extension)

Pest Exclusion Training Module:

https://sites.aces.edu/group/commhort/vegetable/SitePages/pestexclusion.aspx

Part 1. Principles of Insect Exclusion:

http://youtu.be/ZMf_2i5sW3k?list=PL7KYGcKptHx_IhC62646m3QOuLySXQRns

Part 2. How to Build a Net House for Vegetable Production:

http://youtu.be/HIvJf8bNXQg?list=PL7KYGcKptHx_IhC62646m3QOuLySXQRns

Part 3. Low-cost Net Houses for Community Gardens and Urban Farms:

http://youtu.be/hW2bp7g5pkA?list=PL7KYGcKptHx_IhC62646m3QOuLySXQRns

To find other IPM training modules and publications suitable for small farms, visit the Alabama Vegetable IPM website.

This article was originally published here: http://www.southernsare.org/Educational-Resources/Bulletins/Southern-SARE-Bulletins/High-Tunnel-Pest-Exclusion-System-A-novel-strategy-for-organic-crop-production-in-the-South

Download High Tunnel Pest Exclusion System: A novel strategy for organic crop production in the South in PDF Format