Introduction

High tunnels offer a vertical production environment that is often not fully utilized. Hanging baskets of petunias were selected by the PI and cooperating farmer as a trial crop for economic evaluation due to their ability to ‘harvest’ sunlight while, potentially not interfering with the production of other tunnel crops grown below. The production of hanging baskets in an unheated high tunnel also would represent as dramatic decrease in fuel inputs compared to a heated greenhouse for hanging baskets. Risks include the shading of an in-ground tomato crop and spread of insects and diseases

Materials and Methods

Multiple colors of ‘Shock Wave Petunias’ (Ball Seed Company, Chicago, Ill) were seeded on February 20, 2009 (pelleted seed) in a commercial potting mix (Promix, Premier Horticulture, Quebec). These were subsequently transplanted to 48-cell transplant flats at the 2-leaf true stage. A final transplant took place on April 22, when four plants per 12-inch hanging basket were transplanted and hung on the hoop-cross pieces of a 20 by 120-foot unheated high tunnel. Baskets were hung at a density of 16 square feet per basket, a total of 120 baskets. A portion of the tunnel was left without baskets as a control. Irrigation was accomplished with drip emitters, fertigation twice per

week with 20-20-20 plus micronutrients (Millers Nutri-Leaf Greenhouse Grade) at 150-200 ppm Nitrogen, plus phosphoric acid sufficient to achieve irrigation water pH of 6.2, per grower standards.

Seeds of Mtn. Fresh tomatoes (obtained from Sieger’s Seeds) were also seeded on February 20 and subsequently transplanted to 48-cell flats and then 4-inch pots once foliage from adjoining plants began to shade each other. Tomatoes were then transplanted into the tunnel soil, a Lima silt loam soil (pH 6.6), with 4 blocks of 5 plants each randomized under baskets and 4 blocks of 5 plants each randomized without any overhead baskets. Black plastic mulch and drip tape (Chapin Watermatics, 1.0 GPM/100’, 4-inch emitter spacing) were laid prior to transplanting. Plants were irrigated as needed and fertilized with 12-48-8, 20-20-20 and 9-15-30 plus micronutrients at a rate of 100-200 ppm N throughout the season, per grower practice.

Petunia baskets were ‘pinched’ twice to promote branching. A Cornell Vegetable Program Technician scouted weekly for pests and diseases. Baskets were removed from the tunnel over a 4-week period beginning in early May with all sold by the end of the month. Price data was collected for all baskets sold at the Finger Lakes Produce Auction (Penn Yan, NY). Tomatoes were harvested multiple times per week from June 16 to September 14. Total weight of fruit per block was recorded at each harvest. Data were analyzed using statistical software Analysis of Variance (ANOVA) procedure, and treatment means (baskets vs. no-baskets) were separated using Fisher’s Least Significant Difference (p<0.05).etween the flowers and vegetables.

Results

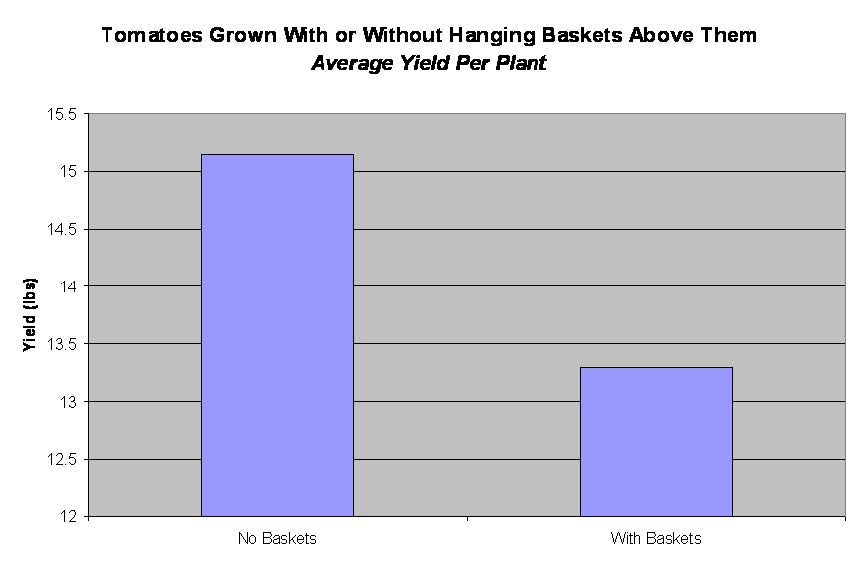

Tomatoes grown under the baskets gave a mean yield of 13.3 lbs per plant compared to 15.15 lbs per plant for those with no overhead baskets (chart 1). Baskets received an

average price of $10.01. There were no recorded insect or disease issues on either crop.

*Means with different letters differ significantly according to Fishers Protected LSD (p<0.05)

Chart 1. Tomatoes under baskets yielded 1.85 pounds less than those without overhead baskets.

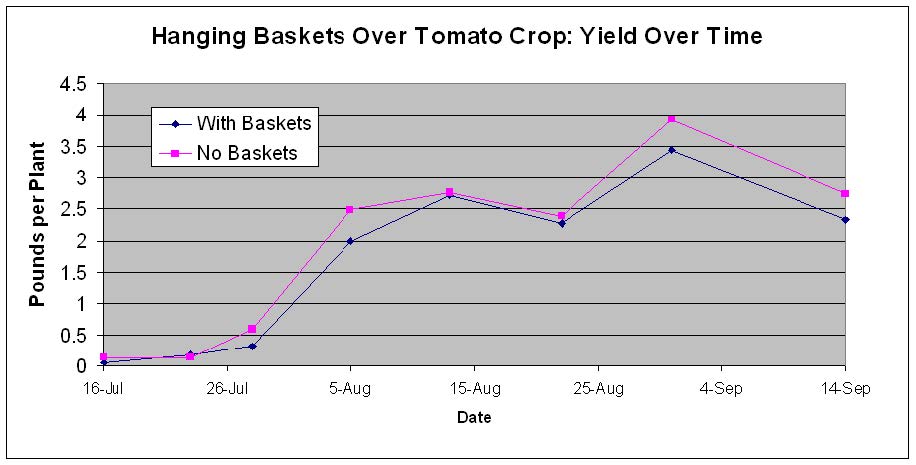

Chart 2. Yield loss was consistent over time.

Economic/Labor inputs

Total labor for the project was calculated and applied a nominal labor rate of $10.00/hour (Table 1).The cooperating grower then estimated a $5.60 input cost per basket (Table 2).

Table 1. Labor estimate per 12″ basket.

| Task | Hours | Cost |

| Seeding | 1 | 10 |

| Transplant | 2 | 20 |

| Transplant | 2 | 20 |

| Potting-up and hanging baskets | 3.5 | 50 |

| Pinching/weekly maintenance | 5 | 50 |

| Total | 15.5 | 155 |

Table 2. Input costs per 12″ hanging basket.

| Expense | Cost (in dollars) per 12” basket |

| Seed | 0.75 |

| Potting soil | 1.2 |

| Basket | 1 |

| Fertilizer | 0.5 |

| Irrigation water | .1 |

| Transplant (GH cost) | 0.75 |

| Labor (per table 1) | 1.3 |

| Total | 5.6 |

Discussion

Baskets appear to have reduced the yield of tomatoes grown underneath them. This is likely due to shading of the tomato foliage. Yield reduction was consistent across time (chart 2), even though the baskets were removed in late May. The baskets themselves performed well economically with a wholesale gross of 10.01 per basket, netting 4.41/basket (after expenses are deducted). Hanging petunias baskets would give a net return of 771.75 per tunnel, if the tunnel were planted uniformly at a density of 16 sq ft per basket (175 baskets in 2800 sq ft).

However, this net return should be adjusted for the yield reduction in tomatoes. The grower reported a wholesale gross of $ 0.6 per pound of tomato. The yield loss of 1.85 pounds per plant over 2800 sq ft of tunnel (560 plants) equals a reduction of $643.80 in tomato income. Deducting this loss from the petunia net return, we come to a new net of 127.95 for all the baskets per tunnel or 0.73 per basket. At this low return, the system appears marginally profitable, yet increases the risk of insect and/or disease transmission from petunias to tomatoes. These include thrips, aphids, Tomato Spotted Wilt Virus, Botrytis Gray Mold and others.

Future Work

Although this work did not give favorable results for the combination of baskets and tomatoes in a high tunnel, firm conclusions should not be drawn from a single trial. Thus, the Cornell Vegetable Program will continue to evaluate hanging baskets in high tunnels. Could a lower density of baskets be grown without affecting tomato yield? This question will be answered in a NESARE funded trial in 2010. Multiple combinations of petunias and other cold tolerant flower species will be evaluated for economic performance. These baskets will be hung in blocks of different densities to measure yield impact on the understory crop. Data to be collected includes:

• Photosynthetic active radiation (PAR) under the different blocks of baskets

• Economics of low-to-no heat hanging baskets based on farm gate value of petunias and tomatoes.

• Tomato yield under different basket densities (including a no-basket treatment)

• Any pest/disease interactions between the crops

The author expresses gratitude to the New York Farm Viability Institute for their support of this work. Questions or comments can be directed to Judson Reid, Cornell Vegetable Program, <jer11@cornell.edu>

Figure 2. Cornell Vegetable Program technician Kathryn Klotzbach scouts for pests.